Add Your Heading Text Here

Add Your Heading Text Here

MELSEC iQ-F series

Designed on the concepts of outstanding performance, superior drive control and user centric programming, Mitsubishi’s MELSEC-F Series has been reborn as the MELSEC iQ-F Series.

From stand alone use to networked system applications, MELSEC iQ-F Series brings your business to the next level of industry.

Concept

Designed on the concepts of outstanding performance, superior drive control and user centric programming, Mitsubishi’s MELSEC-F Series has been reborn as the MELSEC iQ-F Series.

From stand alone use to networked system applications, MELSEC iQ-F Series brings your business to the next level of industry.

New micro PLC designed on the concepts of …

- High-speed system bus

- Extensive built-in functions

- Enhanced security functions

- Battery-less

- Easy built-in positioning (4-axis 200 Kpps)

- Simple interpolation functions

- 4-axis synchronous control with simple motion module (dedicated positioning software not needed)

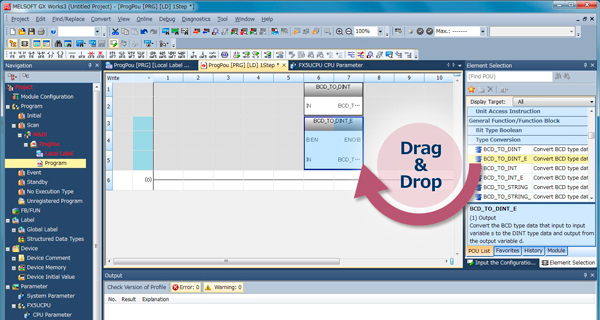

- Easy programming by drag and drop

- Reduced development time with module FB

- Parameterized setup for a variety of functions

PLC & HMI

- High-speed bus performance greatly enhances the total system performance with the high-speed system bus performance (150× conventional speed*1)

- Standardize programs with pre-defined module function blocks and module labels

- Uniform and powerful security functions *1 : Comparison with FX3U

Network

- Achieve loss-less retrieval with CC-Link IE Field 1 Gbps high-speed communication(link refresh performance 40 × conventional levels*1)

- Seamless connectivity with each device using SLMP*2 *1: Comparison with FX3U *2: SLMP: SeamLess Message Protocol

Engineering Environment

- The intuitive programming environment of GX Works3 reduces development cost.

- Module configuration drawings can be generated through direct reading from actual hardware.

- Share parameters across multiple engineering software via MELSOFT Navigator.

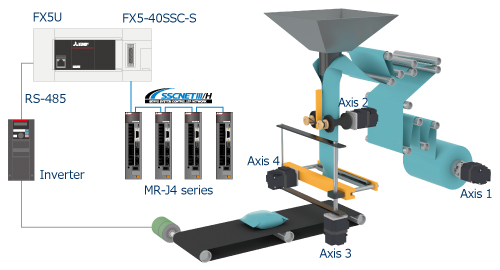

Built-in Positioning (200 kpps, 4 axes built in) + Positioning 2 axes (200 kpps, 2 axes)

Positioning capable of 20 μs high-speed start

FX5U/FX5UC is equipped with built-in positioning functions that can utilize 8ch high speed counter function and 4 axes pulse output. In addition to the existing interrupt stop operation and variable speed operation, new functions have been added and made even easier to use. Furthermore, up to four high-speed pulse I/O modules can be connected for affordable multi-axis control.

High-speed pulse I/O module (Positioning function (2 axes))

Positioning function (2 axes) built in

The high speed pulse I/O module is an I/O module with positioning functions and high speed counter functions added.

Realize 6 axis control by expanding FX5U/FX5UC.

Simple Motion Module (4-axis control module)

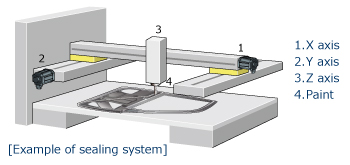

Positioning Control with SSCNET III/H

FX5-40SSC-S is equipped with a 4-axis positioning function compatible with SSCNET III/H.

By combining linear interpolation, 2-axis circular interpolation and continuous trajectory control in the program set with a table, a smooth trajectory can be easily drawn.

Advanced Motion Control

Making Simple Motion with compactly packed extra functions

By starting with parameter settings and the sequence program, the Simple Motion modules can realize a variety of motion control including positioning control, advanced synchronous control, cam control and speed-torque control.

Use synchronous control and cam control to build a system perfect for your equipment.

Register up to 64 types of cam patterns to respond to any type of packaging needs.

Perform continuous operation without stopping the workpiece operation.

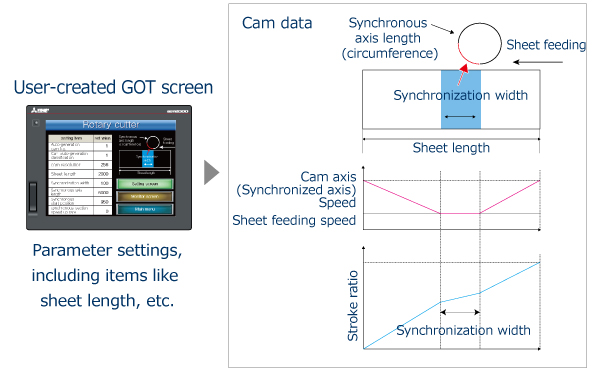

Synchronous control

In addition to synchronous control that replaces physical machine mechanisms such as gears, shaft, transmission and cam with software, functions such as cam control, clutch and cam auto-generation are easily realized. Since synchronous control can be started and stopped for each axis, programs can contain both synchronous control axes and positioning control axes. Up to four axes can be synchronized to the synchronous encoder axis, enabling use with a variety of systems.

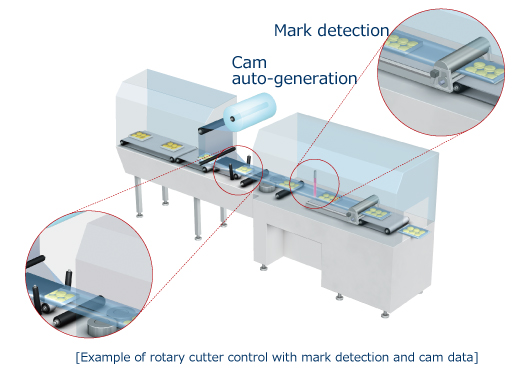

Cam data auto-generation

Easily program and automatically generate difficult cam data for rotary cutters just by inputting the sheet length, synchronization width, and cam resolution, etc.

Mark detection function

The cutter axis deviation can be compensated by detecting a mark on the workpiece so the workpiece can be cut at a constant position.

Software for comprehensively supporting the design and maintenance of sequence programs.

Easily and intuitively program by making “selections” in a graphical environment.

Reduce maintenance and engineering costs with diagnosis and troubleshooting function.

System design with a convenient parts library

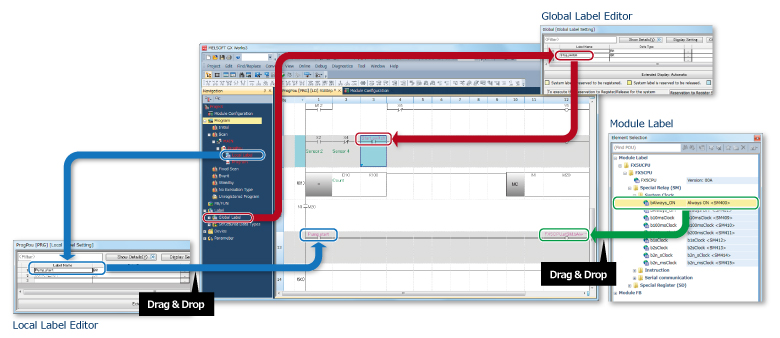

With GX Works3, designing a system is as easy as preparing the module configuration diagram by dragging and dropping selected parts.

Auto-generation of module parameters

When preparing the module configuration diagram, simply double-click the module to automatically generate the module parameters.

A window with an easy-to-use parameter settings screen opens, enabling module parameters to be modified as needed.

Main programming languages supported

The main IEC languages are supported by GX Works3. Various different programming languages can be used within the same project simultaneously and can be viewed easily via the menu tab.

The labels and devices used in each program can be shared across multiple platforms, with user defined function blocks supported.

Reduce repetitive program tasks

Global labels, local labels and module labels are supported by GX Works3. Global labels can be shared by multiple programs and with other MELSOFT software. Local labels can be used in registered programs and function blocks. Module labels contain buffer memory information for various intelligent function modules. Therefore, buffer memory addresses need not be referenced when programming.

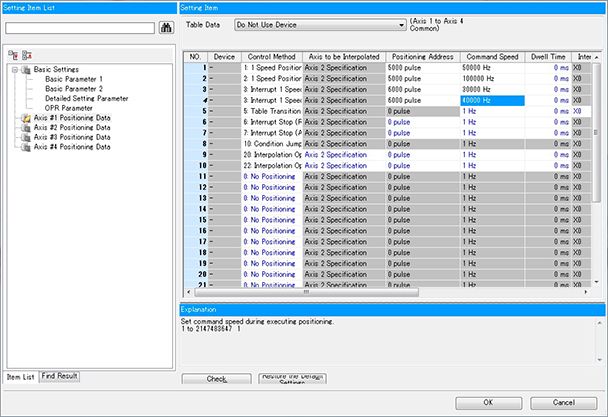

Integrated motion setup tool

GX Works3 is equipped with a special motion setup tool that makes it easy to change simple motion module settings such as module parameters, positioning data and servo parameters. Also, the servo adjustment is simplified using it.

System Configuration

Synchronized Control Parameter

Digital Oscilloscope

Simple and convenient parameter settings

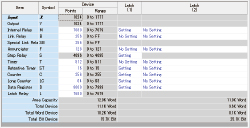

With MELSEQ iQ-F, various device settings that conventionally had to be programmed can be input in table format.

Easily set the built-in functions as well as expansion devices just by inputting values into the parameters.

The program’s execution trigger can also be set with the parameters.

[Functions set with parameters]

Settings for CPU parameters, Ethernet port, RS-485 communication port, input response time, expansion board, memory card, security, etc.

Settings for expansion adapter, intelligent function module and program parameters

Memory area for each application

The CPU module has 64 k steps of program memory capacity, but the MELSEC iQ-F has a memory data area for each application, so all 64 k steps can be used as the program area.

Comments and statements can be written freely without affecting the program area.

[Maximum number of characters]

Comment: 1024 characters Statement: 5000 characters

MELSEC iQ-F Series stores the program and devices in non-volatile memory such as Flash ROM, so no battery is required.

Flexible internal devices

A variety of devices including new latch relays and link relays, and expanded timers and counters are available.

The number of device points can be reassigned and used in the internal memory.

●Providing the convenience of special devices In addition to the conventional special devices, up to 12000 points of convenient system devices compatible with upper level devices are added. New upper level compatible system devices

SM/SD0 to 4099 Conventional convenient devices

| ●Freely customize the latch range setting The latch range can be set for each device, so the latch clear range can be selected during the clearing operation.  | ●Handy timer and counter settings The timer and counter properties are determined by data type and how instruction is written, so programs can be created regardless of the device number. Timers:

Counters:

|

Dramatically more dedicated instructions

A great number of dedicated instructions have been added since the FX3 Series.

| [FX3] 510 types | → | [FX5] 1014 types |

The newly added instructions include convenient ones that are interchangeable with the MELSEC iQ-R and dedicated instructions for built-in functions.

(Programs created with GX Works2 can also be read in and converted.)

Intuitive and easy-to-understand arithmetic operations

Symbols can be input in the arithmetic operations making it easy and intuitive to describe programs.

High-performance built-in high-speed counter function

Input and measure three modes by setting the parameters.

- Normal mode

- Pulse density measurement mode

- Rotation speed measurement mode

Up to 32 tables can be set for the high-speed comparison table and up to 128 tables for the multi-point output high-speed comparison table. The DHCMOV instruction can be used to read the latest values from the special registers.

Reinforced built-in positioning function

Positioning is easy using table operations. Simple linear interpolation operation is possible by using the DRVTBL with multiple table operation and the multiple axis table drive DRVMUL.

Diverse table operation settings for multi-speed and interrupt positioning, etc.

Inverter communication command function

*: For built-in RS-485 and RS-485 expansion boards

The built-in Mitsubishi inverter protocol makes it possible to use inverter communication instructions to control a Mitsubishi inverter connected with RS-485 communication.

- IVCK: Operation monitor

- IVDR: Operation control

- IVRD: Parameter read

- IVWR: Parameter write

- IVBWR: Parameter batch write

- IVMC: Multiple command (2 types of settings and 2 types of read)

Built-in Ethernet function

Communication is set with parameters easily.

Functions including the diagnosis function from GX Works3, SLMP function, socket communication function and IP address change function and unauthorized access from an external source can be prevented with remote password.

MODBUS function

The MODBUS function can be used with parameter settings and ADPRW (MODBUS master communication instruction [data read/write.]) Communicate with devices up to 1200 m away using the RS-485 communication adapter.

Standard function/function block function

110 types of basic standard function and function blocks are provided.

These can be used as parts by dragging and dropping, so when used together with dedicated instructions, programming time can be greatly reduced.